An Indian scientist has invented an automated system for the repair and restoration of high-value components that require minimum human participation, such as moulds, turbine blades, and aircraft components.

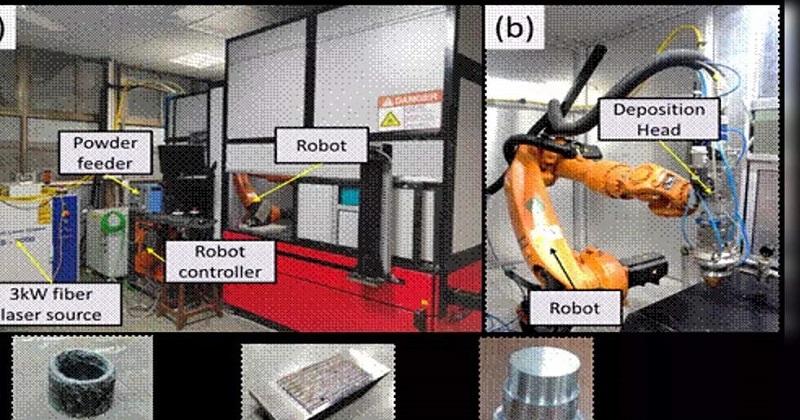

A faulty component that requires repair will be scanned autonomously for damage detection with a laser scanner, and the deposition path will be selected based on particular algorithms with the assistance of the technology. The material will be deposited using the laser-directed energy deposition (LDED) technology, followed by finishing and automated inspection of the repaired product.

Existing repair processes, such as welding and thermal spraying, are haphazard and lack precision. Furthermore, all present technologies are manual, and the quality of repair is determined by the skill level of the individual performing the work. The technology is projected to propel the restoration and repair sector forward by creating a cutting-edge laser manufacturing environment that would enhance Atmanirbhar Bharat.

Professor Ramesh Kumar Singh of Bombay’s IIT-mechanical engineering department developed the technology, which employs a laser for process control and assures better quality and reproducibility in repair.

Also Read: Actress Vijayalakshmi meets son after 3 months; See the heartfelt video

The technique has been validated and tested, thanks to funding from the advanced manufacturing technologies initiative of the department of science & technology. According to a statement from the S&T department, the system is a robotic restoration system that is meant to work autonomously for all critical tasks such as scanning route planning, damage identification, deposition, finishing, and inspection.

For industrial uptake, Singh has partnered with Bharat Forge, Aditya Birla Science and Technology Company, and Interface Design Associates. ‘The technology is very impactful, and a game-changer for the restoration and repair segment of the manufacturing industry and has huge market potential. The components which can be reconditioned via this technology are very high value. The level of accuracy and precision, which is possible through this technology, is far ahead of the current state-of-the-art methods’, he said.

Post Your Comments