Carmakers have concentrated on range in the race to become electric to allay consumer concerns about the infrastructure for charging, but battery manufacturers are already developing the smaller, more durable, and less expensive batteries of the future, which also charge more quickly.

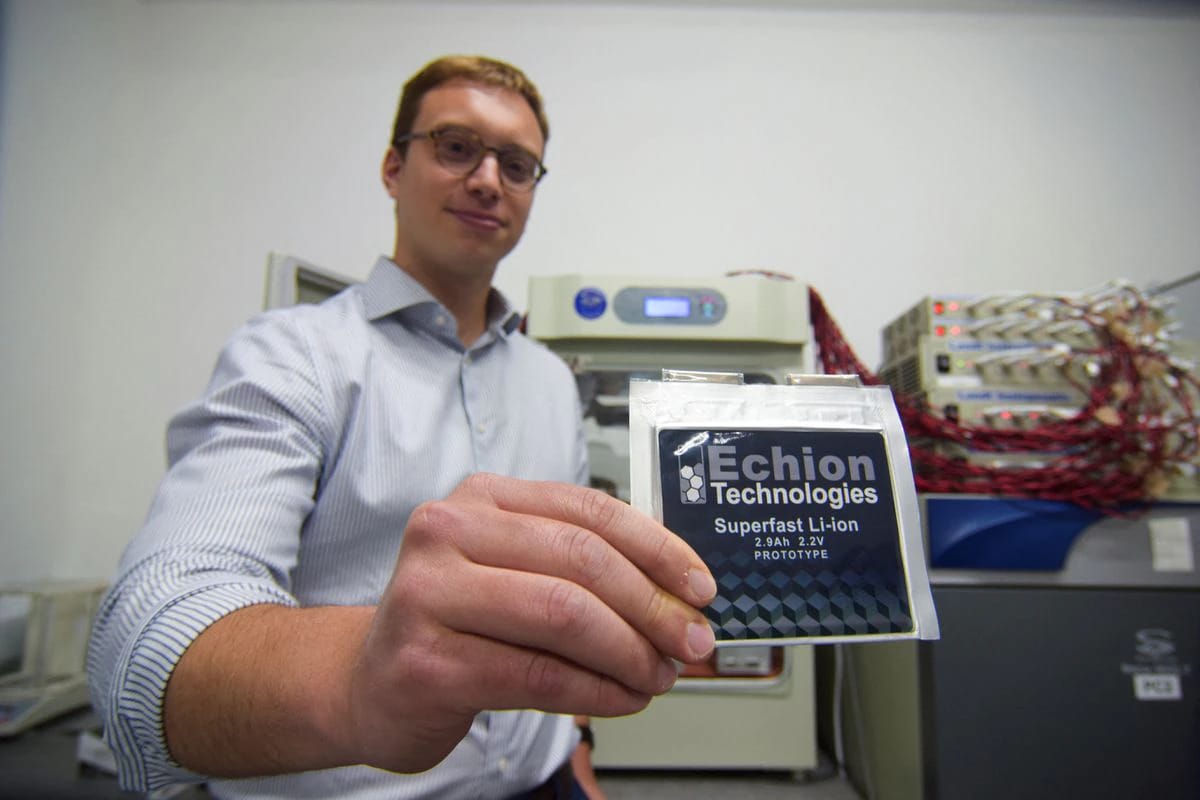

While automakers compete with Tesla, the market leader, to produce vehicles that can go at least 300 miles (482 km) between charges, battery startups anticipate that as public EV chargers proliferate, range will become less of an issue. Startup companies are experimenting with materials like silicon-carbon, tungsten, and niobium in their quest for smaller batteries that charge very quickly.

Since the battery is the most expensive component of an EV, true fast charging along with widely accessible chargers – a lack of which is currently thought to be slowing broader adoption of EVs – would enable automakers to build cars with smaller batteries at more affordable prices while boosting profit by selling more vehicles to a wider audience.

Sai Shivareddy, CEO of Nyobolt, a start-up researching niobium oxide anode materials for batteries that can charge in minutes, stated that early adopters at the top end of the market desired bigger battery packs and longer range because they could afford it. ‘You need smaller battery packs for more cost-conscious mass acceptance, but with the same experience as today (with fossil-fuel automobiles), where you can fill up in 5 minutes.’

China produces the majority of the world’s EV batteries, but businesses like Contemporary Amperex Technology Co (300750.SZ) are working to make batteries that can last longer between charges.

Chinese automakers have launched affordable, compact EVs like the Wuling Hongguang Mini, which is still available for about $6,500 despite recent increases in battery prices. SAIC Motor Corp Ltd (600104.SS), General Motors Co, and Wuling Motors collaborated to create the vehicle (0305.HK).

Post Your Comments