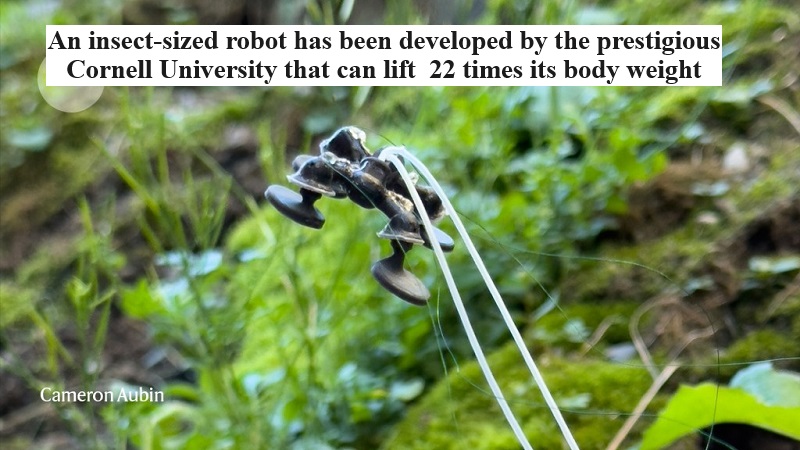

Cornell University, a renowned institution, has engineered a minuscule robot with the remarkable ability to hoist a load 22 times its own weight. As disclosed in a recent Cornell Chronicle report dated September 18, this innovation is the brainchild of materials engineer Robert Shepherd and his PhD student Cameron Aubin, in collaboration with their peers, all hailing from Cornell University situated in Ithaca, New York.

This robot is exceedingly compact, measuring just a tad over an inch in length and weighing approximately as much as one and a half paper clips. Its construction relies on cutting-edge 3D-printing technology, utilizing a flame-resistant resin. Notably, the robot’s body houses two discrete combustion chambers that lead to its four actuators, serving as its functional feet.

Each actuator assumes the form of a hollow cylinder, capped with a layer of silicone rubber akin to a drum skin on its underside. A pivotal aspect of this design is its capacity to ignite a controlled combustion reaction through external electronics, resulting in the inflation of the drum skin, consequently propelling the robot into the air, as elucidated in the report.

What sets this robot apart is its unique reliance on combustion as a power source, granting it capabilities previously unattainable by robots of its diminutive scale. Cameron Aubin attested to its astonishing jumping ability relative to its size and its remarkable ground speed, all owing to the extraordinary force density and power density of these fuel-driven actuators.

Moreover, the actuator’s design furnishes the operator with a high degree of control. Through the simple act of adjusting a knob, one can manipulate the sparking speed and frequency or even modulate the fuel supply in real-time, thereby eliciting a versatile range of responses from the robot.

Cameron Aubin underscored the vast potential applications of these insect-scale robots, such as search and rescue missions, exploration, environmental monitoring, surveillance tasks, and navigating challenging terrains. While a fully untethered model remains a work in progress, the current iteration of this robot undoubtedly outperforms its competition in terms of force output, signaling an exciting development in the realm of micro-robotics.

Post Your Comments